Wire & Cable

The energy cable has revolutionized various facets across multiple industries over the last couple of decades. Induction heating is used for entire tube annealing, hardening and tempering, etc.

The wire and cable industry are spread across the globe and used for every other application or product. It is an integral part of every industry and ever present in our daily lives. The tube and pipe industry are closely connected to other sectors and as the demand increases within these sectors, this industry had to adapt to meet the needs of these sectors.

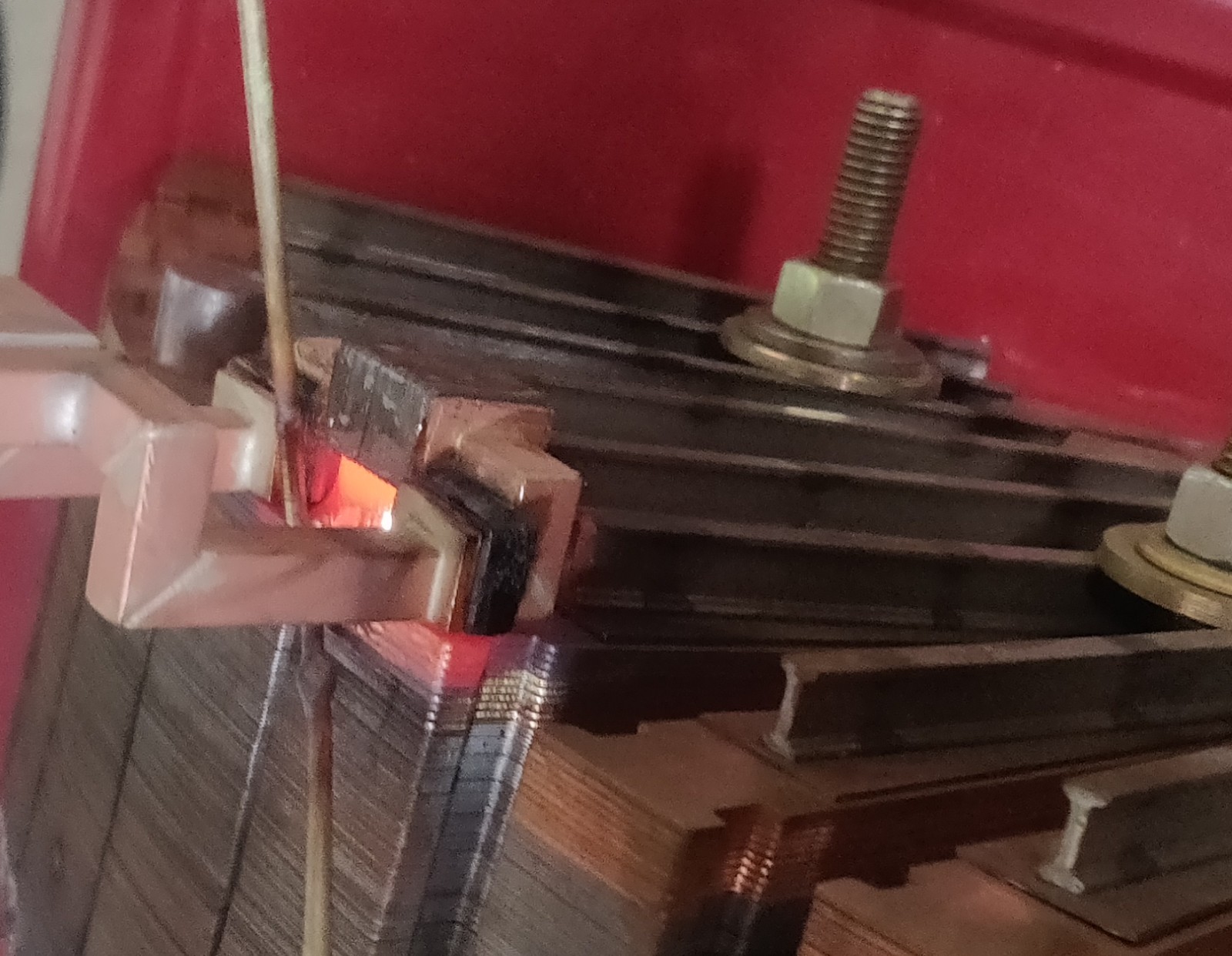

Induction heating within this industry is being used in processes for induction welding, tube annealing, seam annealing, hardening, tempering and stress relieving. Induction heating is increasingly being used because of its high energy efficiency, ability of in-line production integration, precise temperature control and high dimensional accuracy.

Joining Processes

- Tube and profile continuous welding (Inductive and conductive)

- Tube and pipe brazing

Heat Treatment

- Hardening and tempering

- Entire tube annealing

- Seam annealing

- Bright annealing

- Stress relief

Pre and Post-Heating

- PWHT (Post Welding Heat Treatment)

- Preheating for welding, coating, drying and forging