Automotive

Automotive industries Induction heating machines are integral in the manufacture of many parts along the automotive drive train-including CV joints, tulips, gears, steering racks and wheel hubs.

The automotive industry has undergone several evolutions in a span of 100 years to attain truly autonomous vehicles. The automotive industry is a major contributor to the global economy.

The automotive industry comprises of several varied economic activities. In just over 100 years these activities have achieved a high degree of both social and economic importance worldwide. Recent initiatives for lean, just-in-time manufacturing within the automotive industry have emphasized the need to find faster and more efficient heating technologies.

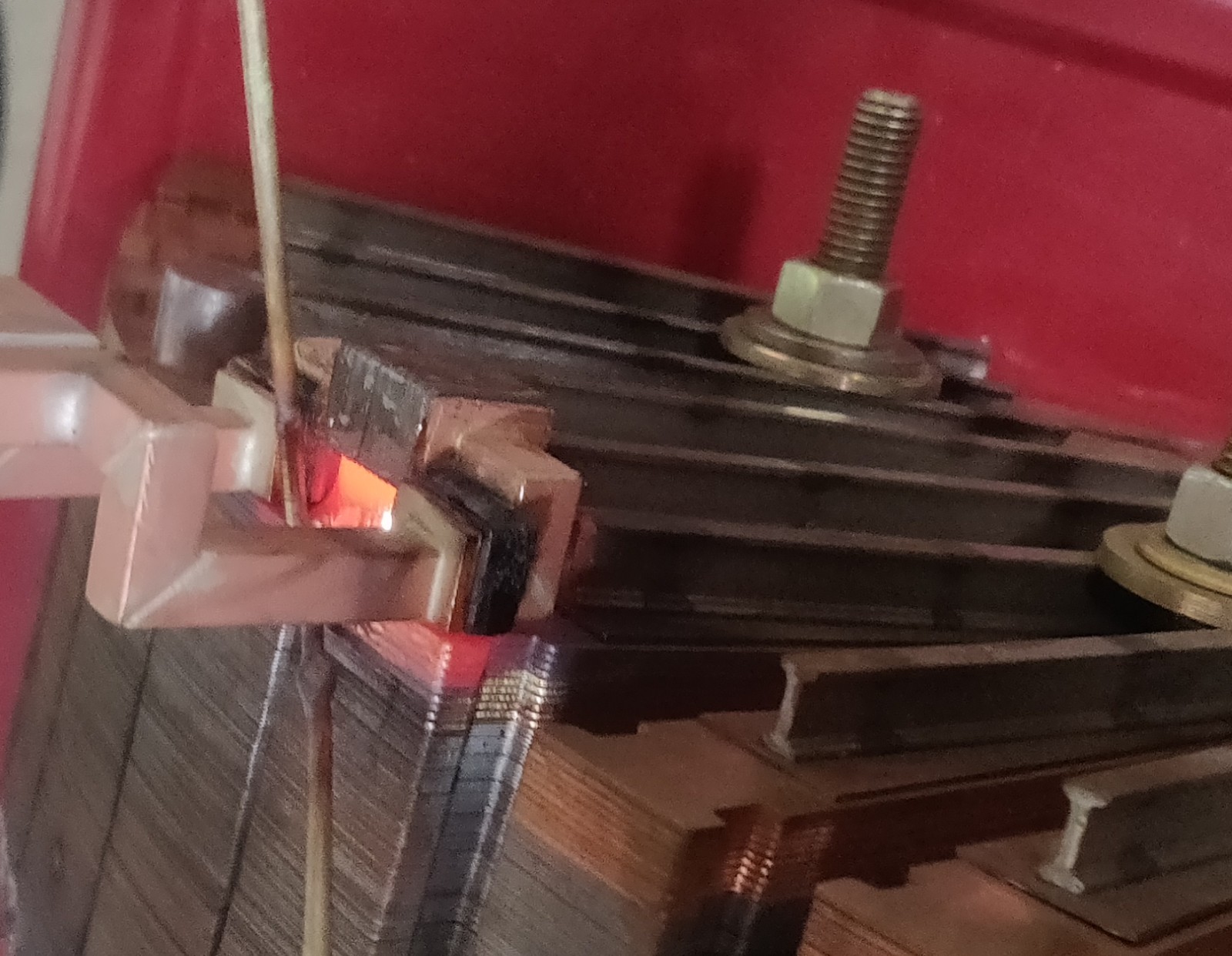

Induction heating machines are used in the manufacture of many parts along the automotive drive train – including CV joints, tulips, gears,

steering racks, and wheel hubs. Induction technology is also used to produce large body and engine parts such as rocker arms, cam shafts, valves, connecting rods, banding, crank shafts, and starting rings.

Finally, shock absorber components are hardened and formed using induction.

Induction heating is a quick, clean, non-contact method of inducing heat for a wide variety of metal joining and heat-treating applications. When compared to convection, radiation, open flame or other heating methods, induction heating offers substantial advantages:

• Increased consistency with solid state temperature control & closed loop monitoring systems.

• Maximized productivity with in-cell operation; no soaking time or lengthy cool down cycles.

• Improved quality with minimized product warpage, distortion and reject rates.

• Extended fixture life with site-specific heat without heating any surrounding parts.

• Environmentally sound without flame, smoke, waste heat, noxious emissions or loud noise.

• Reduced energy consumption with up to 80% energy efficiency